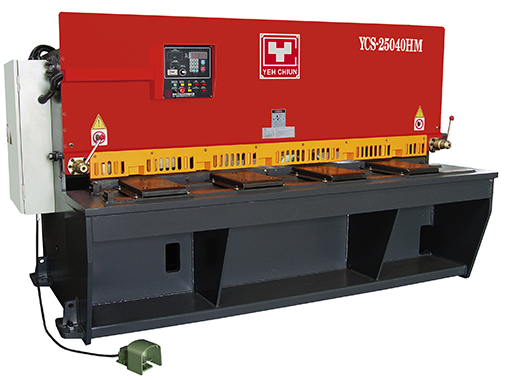

Hydraulic Shear

NC Hydraulic Guillotine Shear

A hydraulic guillotine shear is a machine that cuts metal or other materials with a sharp blade that moves up and down by hydraulic power. It can make clean and precise cuts on metal in different forms, such as plates, sheets, or rods. The cut metal can then be shaped or bent on another machine.

Yeh Chiun hydraulic guillotine shearing machine has a sturdy and compact design with an adjustable shearing angle. Our YCS-HM Model can cut metal sheets with lengths from 0.1-9.9M and thicknesses from 0.1mm to 25mm. For other detailed specifications of our hydraulic guillotine shear, you can find out through the table below.

| Back Gauge Brake Motor | |

| Speed | 1420 RPM |

| Reduction Ratio | 10 : 1 |

| Accuracy | + / - 0.1 mm |

| Stroke | 800 mm |

| Shear Length | 0.1-9.9M |

| Counter | 9999 |

Manual Blade Gap

Adjustment Device

Hand protection device

YCS-HM CONTROLLER SYSTEM

- OBLONG FRONT SCALE 1400 mm

- FRONT FRAME 1400 mm

- FRONT GAUGE SETTER

- FRICTIONLESS BALL ROLLER WORKING TABLE

- SHADOW LINE

- HAND PROTECTION DEVICE

- SCRATCHPROOF RUBBER PUSH PAD

- MAINTENANCE AND OPERATIONAL MANUAL

- TOOLS FOR MAINTENANCE (BOX)

- Hydraulic guillotine shear acts in a vertical up and down manner, which is enables by synchronized hydraulic cylinders and direct fixing mechanism of the upper blade. The sheared edge is burr free and precise.

- Unique hydraulic control adjusts automatically the output of holddown cylinders according to the magnitude of the load. Shearing thickness ranges from 0.1mm to 25mm

- Logic hydraulic circuit, controlled by sequence valves functions at a low level of noise with no vibration. Stability as well as normal fluid temperature of hydraulic components can be maintained under high-speed and long-lasting operations to assure consistent performance of the shear.

- The shear body and blade base are made of SS400 steel plates which have been annealed for the elimination of internal stress. Control functions are integrated in the front side of the shear for the ease of operations.

- Overload protection ensures the safety of the shear and operators.

- Special design of blade offers easy adjustment of blade's clearance. It can remain the shearing section and machine's safety by pushing buttons or Controllers calculate.

- Back gauge is driven by brake motor and precision ball screw to cut accurately and precisely.

- Back gauge dual U overhang linear guide.

- Easy back gauge calibration.

- Pre-retreat of back gauge to thick sheet cutting.

- The controller maintains functional in the environment of highvoltage electromagnetism.

※Automatic sheet support system provides extreme long plate shearing and protection from scratch. The support's quick response to plate support and descent makes the shearing even more accurate and smoother. (OPTIONAL)